Boron Carbide

Boron carbide, B4C, is one of the hardest materials in the world, ranking third behind diamond and cubic boron nitride, and it is the hardest material produced in tonnage quantities. Discovered as a byproduct in the production of metal borides during the 19th century, it is produced by reacting carbon with B2O3 in an electric arc furnace through carbo-thermal reduction or gas phase reactions.

Request a FREE Quote

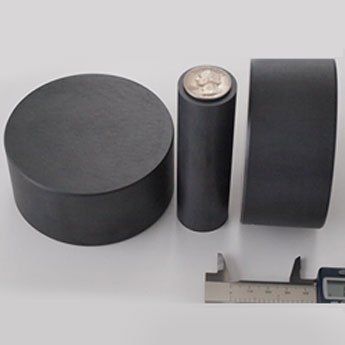

Boron carbide must be milled and purified to remove metal impurities prior to commercial use. It has a density of 2.52, a hardness of 2,900-3,580, melts at 2445°C, has a toughness between 2.9 to 3.7, an electrical conductivity of 140, a thermal conductivity of between 30 and 42, thermal expansion of 5, thermal neutron cross section of 600, and a Young’s Modulus of 450 to 470. Its characteristics include:

- Erosion Resistance

- High Hardness

- High Modulus

- Lightweight

- Neutron Absorber

Boron Carbide Applications

Abrasives

Due to its high hardness, Boron Carbide Powder is used as an abrasive in polishing and lapping applications also as a loose abrasive in cutting applications such as water jet cutting. It can also be used for dressing diamond tools.

Nozzles

The extreme hardness of Boron Carbide (B4C) gives it excellent wear and abrasion resistance and as a consequence it finds application as nozzles for slurry pumping, grit blasting and in water jet cutters.

Nuclear Applications

Its ability to absorb neutrons without forming lived radio-nuclides make the material attractive as an absorbent for neutron radiation arising in nuclear power plants. Because of its B10 isotope Boron Carbide applications include shielding and control rod and shut down pellets

Combustion in Solid Fuel Ramjets

The effect of bypass air momentum on the combustion efficiency of a Boron Carbide fueled solid fuel ramjet has been investigated theoretically. A 3D model of the flow in the aft-burner has been developed and solve numerically. The theoretical results indicate that combustion efficiency can be increased by employing bypass air with low dump momentum, in agreement with experimental results. High bypass air dump momentum was shown to enhance extinguishing of particle combustion through increased collisions with the motor walls.

Ballistic Armour

Boron Carbide (B4C) in conjuction with other materials also find use as ballistic armour for personal and military use, the combination of high harness, elastic modulus and low density give the material an exceptionally high specific stopping power to protect high velocity projectiles.

Other Applications'

Boron Carbide evaporation boats for material testing mortars and pestles, ceramic tooling dies, precision toll part

Boron Carbide Dressing Sticks

We make dressing sticks fully dense and larger for a longer life. Ideal for off-hand truing and dressing of medium grit, soft and medium-grade vitrified grinding wheels, our sticks are 4” x ½” x ¼” thicker and longer, making them easier to use and more cost-efficient.

Request a FREE Quote

• Watch Our Boron Carbide Video •